ENGINEERING & TECHNOLOGIES

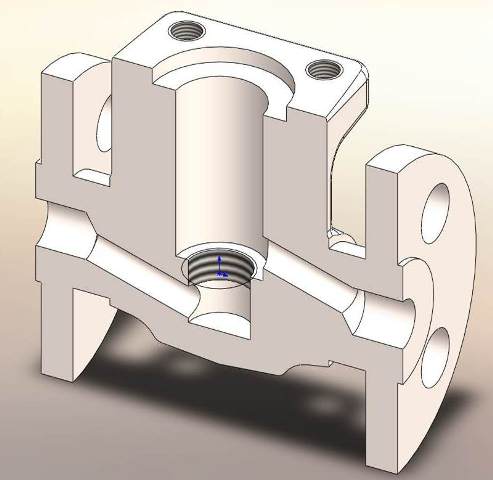

MTM VALVES is a fast growing Company thanks also to the use of CAD systems technology and, in particular, of Solidworks, which is always updated with the latest products. Moreover, the use of:

- Solidworks FlowSimulation®

- Solidworks Simulation®

together with our human resources enabled the Company to achieve the highest level in designing new products and meeting Customer’s need.

|

SOLIDWORKS®

|

||

| |

||

SOLIDWORKS SIMULATION® SOLIDWORKS SIMULATION® SolidWorks Simulation provides core simulation tools to test designs and make the decisions to improve quality. The full integration creates a short learning curve and eliminates the redundant tasks required with traditional analysis tools. Component materials, connections, and relationships defined during design development are fully understood for simulation. Products can be fully analyzed and ested for strength, safety and kinematics. |

||

|

|

||

FLOW SIMULATION® SolidWorks Flow Simulation takes the complexity out of computational fluid dynamics. We can quickly and easily simulate fluid flow, heat transfer, and fluid forces that are critical to the success of design. Simulate liquid and gas flow in real world conditions, and quickly analyze the effects of fluid flow, heat transfer, and related forces on immersed or surrounding components. Design variations can be compared to make better decisions, resulting in products with superior performance. Specific modules simplify the specialized analysis of HVAC and electronic cooling. |

||

Newsletter

Subscribe to our newsletters to receive latest news and updates

Experience, quality, service, flexibility, and reduced delivery times are the strenght points of the company, which intends satisfy all customer’s exigencies and requirements, in the market of forged steel valves where to have a valve is necessary waiting for long times.